Managing 100 Million COVID Test Kits

A Logistics Plus® Supply Chain Success Story!Managing the Importing, Warehousing, and Delivery of over 100 million COVID Test Kits

Logistics Plus harnesses the power of its ‘yes’ culture to help a top supplier in the medical device industry pull off a miracle-like roll-out of critical COVID test kits for the Biden Administration.

THE CHALLENGE

Logistics Plus (LP) is a leading worldwide provider of transportation, warehousing, fulfillment, global logistics, business intelligence, technology, and supply chain solutions. In 2020 and early 2021, Logistics Plus leveraged its global network to source, warehouse, and deliver millions of PPE supplies around the world. Based on that expertise, in late December 2021, a top supplier in the medical device industry approached LP with the challenge of rapidly importing, warehousing, and distributing a massive order of COVID test kits for the Biden Administration. One caveat to the project was that the first chartered airplanes were already in flight and enroute to the United States. At the time, most LP warehouses in the U.S. were already filled with other clients’ freight due to supply chain issues associated with COVID.

THE SOLUTION

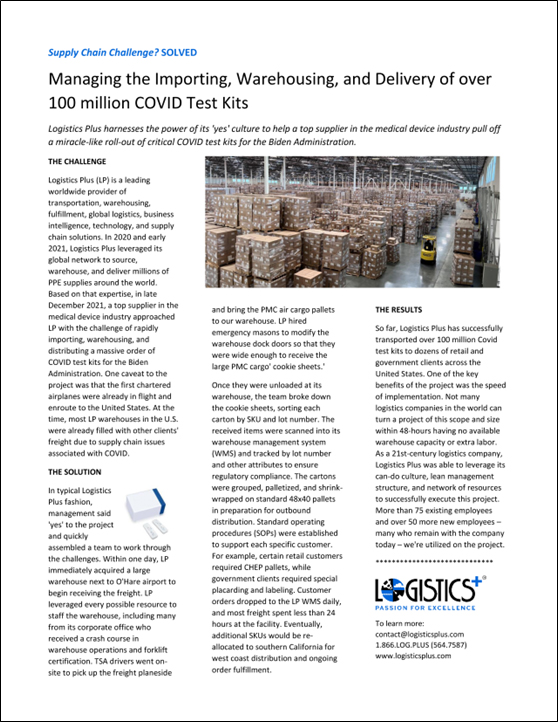

In typical Logistics Plus fashion, management said ‘yes’ to the project and quickly assembled a team to work through the challenges. Within one day, LP immediately acquired a large warehouse next to O’Hare airport to begin receiving the freight. LP leveraged every possible resource to staff the warehouse, including many from its corporate office who received a crash course in warehouse operations and forklift certification. TSA drivers went on-site to pick up the freight planeside and bring the PMC air cargo pallets to our warehouse. LP hired emergency masons to modify the warehouse dock doors so that they were wide enough to receive the large PMC cargo’ cookie sheets.’

Once they were unloaded at its warehouse, the team broke down the cookie sheets, sorting each carton by SKU and lot number. The received items were scanned into its warehouse management system (WMS) and tracked by lot number and other attributes to ensure regulatory compliance. The cartons were grouped, palletized, and shrink-wrapped on standard 48×40 pallets in preparation for outbound distribution. Standard operating procedures (SOPs) were established to support each specific customer. For example, certain retail customers required CHEP pallets, while government clients required special placarding and labeling. Customer orders dropped to the LP WMS daily, and most freight spent less than 24 hours at the facility. Eventually, additional SKUs would be re-allocated to southern California for west coast distribution and ongoing order fulfillment.

THE RESULTS

So far, Logistics Plus has successfully transported over 100 million Covid test kits to dozens of retail and government clients across the United States. One of the key benefits of the project was the speed of implementation. Not many logistics companies in the world can turn a project of this scope and size within 48-hours having no available warehouse capacity or extra labor. As a 21st-century logistics company, Logistics Plus was able to leverage its can-do culture, lean management structure, and network of resources to successfully execute this project. More than 75 existing employees and over 50 more new employees – many who remain with the company today – we’re utilized on the project.