by Scott Frederick | Feb 4, 2026 | News

Logistics Plus Earns Great Place to Work Certification for a Ninth Consecutive Year

In anonymous surveys dating back to 2018, employees consistently rate Logistics Plus as a great workplace.

ERIE, PA (February 4, 2026) – Logistics Plus, Inc. (LP), a global leader in transportation, logistics, and unique supply chain solutions, is proud to be Certified™ by Great Place to Work® for the ninth year in a row. The prestigious award is based almost entirely on what current employees say about their experience working at Logistics Plus. This year, 91% of employees said it’s a great place to work – 34 points higher than the average U.S. company, and 3 points higher than the composite average of the top 100 best companies in America.

ERIE, PA (February 4, 2026) – Logistics Plus, Inc. (LP), a global leader in transportation, logistics, and unique supply chain solutions, is proud to be Certified™ by Great Place to Work® for the ninth year in a row. The prestigious award is based almost entirely on what current employees say about their experience working at Logistics Plus. This year, 91% of employees said it’s a great place to work – 34 points higher than the average U.S. company, and 3 points higher than the composite average of the top 100 best companies in America.

Additional facts from this year’s survey results:

• Over 94% of employees say they are treated fairly regardless of their race, gender, or sexual orientation.

• 94% rate the service that Logistics Plus provides as “excellent.”

• 93% say they are proud to tell others they work here.

• 92% say management is competent at running the business.

• 91% feel good about the ways Logistics Plus contributes to the community.

Great Place To Work® is the global authority on workplace culture, employee experience, and the leadership behaviors proven to deliver market-leading revenue, employee retention, and increased innovation.

“Great Place To Work Certification is a highly coveted achievement that requires consistent and intentional dedication to the overall employee experience,” says Sarah Lewis-Kulin, the Vice President of Global Recognition at Great Place To Work. She emphasizes that Certification is the sole official recognition earned through real-time employee feedback on their company culture. “By successfully earning this recognition, it is evident that Logistics Plus stands out as one of the top companies to work for, providing a great workplace environment for its employees.”

“This coming year, Logistics Plus begins our 30th year,” said Jim Berlin, Founder and CEO of Logistics Plus. “When we started LP in 1996, it was just a handful of people and a lot of hope. We grew. We stumbled. We learned. We adapted. No grand plan. No big investor. Just energy, ideas, and a belief that if we worked harder, cared more, and kept showing up, good things would happen — a true Passion for Excellence. As always, our people are the key to our success.”

According to Great Place to Work research, job seekers are 4.5 times more likely to find a great boss at a Certified Great Workplace. Additionally, employees at Certified workplaces are 93% more likely to look forward to coming to work, and are twice as likely to be paid fairly, earn a fair share of the company’s profits, and have a fair chance at promotion.

Candidates interested in a career with Logistics Plus can visit logisticsplus.com/careers.

About Great Place to Work Certification™

Great Place To Work® Certification™ is the most definitive “employer-of-choice” recognition that companies aspire to achieve. It is the only recognition based entirely on what employees report about their workplace experience – specifically, how consistently they experience a high-trust workplace. Great Place to Work Certification is recognized worldwide by employees and employers alike and is the global benchmark for identifying and recognizing outstanding employee experience. Every year, more than 10,000 companies across 60 countries apply to get Great Place To Work-Certified.

About Great Place To Work®

As the global authority on workplace culture, Great Place To Work® brings 30 years of groundbreaking research and data to help every place become a great place to work for all. Their proprietary platform and For All™ Model help companies evaluate every employee’s experience, with exemplary workplaces becoming Great Place To Work Certified™ or receiving recognition on a coveted Best Workplaces™ List.

About Logistics Plus, Inc.

About Logistics Plus, Inc.

Logistics Plus, Inc. is a 21st Century Logistics Company™. With annual global sales approaching $1 billion, Logistics Plus is a leading global provider of transportation, warehousing, fulfillment, logistics, project management, business intelligence, technology, and unique supply chain solutions. The company is recognized as one of the fastest-growing privately owned logistics companies, with a presence in over 50 countries worldwide. With its trademark Passion for Excellence™, Logistics Plus is consistently recognized as a great place to work and a top global logistics provider. Learn more at logisticsplus.com.

by Scott Frederick | Feb 2, 2026 | News

Logistics Plus Enhances its Global Network with the Acquisition of Evo Supply Chain Pvt. Ltd. to Create a New India Subsidiary

This transition strengthens the ability of Logistics Plus to support customers with localized expertise, expanded capabilities, and a strong team on the ground.

Yuriy Ostapyak (L) and Manish Malik (R)

ERIE, PA and GURUGRAM, INDIA (February 2, 2026) – Logistics Plus, Inc. (LP), a global leader in transportation, logistics, and unique supply chain solutions, today announced the planned acquisition of Evo Supply Chain Pvt. Ltd., which will operate as the new India subsidiary within the Logistics Plus global network. This transaction marks a significant expansion of LP’s footprint in India and replaces the former Logistics Plus India Pvt. Ltd. group, further strengthening the company’s long-term commitment to the region. The transition will proceed alongside routine legal and regulatory processes, with teams on both sides working collaboratively to ensure a smooth integration.

As part of the transition, Logistics Plus has launched a new website, in.logisticsplus.com, highlighting its comprehensive portfolio of services, including international freight forwarding, customs brokerage, trade compliance, and warehousing solutions. The former Evo Supply Chain website (evoscs.com) will be redirected to the new India website to ensure continuity and ease of access for customers and partners.

Manish Malik, Co-Founder and Managing Director of Evo Supply Chain, will continue in his role as Managing Director – India & Subcontinent, ensuring leadership continuity and deep regional expertise. In addition to leading LP’s India operations, Manish Malik will report to LP’s global Chief Operating Officer, Mr. Yuriy Ostapyak, and will be an integral part of LP’s global leadership team, contributing to strategic initiatives across the organization. With over two decades of experience in international logistics, supply chain management, and market development, Manish Malik has played a pivotal role in building scalable, customer-centric logistics platforms in India. His strong understanding of regional trade dynamics, regulatory frameworks, and operational execution has been instrumental in establishing high-performing teams and long-term customer partnerships. The new India organization will be headquartered in Gurugram, with additional offices in Bengaluru, Chennai, and Mumbai.

“The acquisition of Evo Supply Chain represents an important step forward in our long-term global growth strategy,” said Yuriy Ostapyak, Chief Operating Officer of Logistics Plus. “India is a critical market for global trade and manufacturing, and this transition strengthens our ability to support customers with localized expertise, expanded capabilities, and a strong, experienced team on the ground.”

The new India team brings extensive experience across international freight forwarding, customs and regulatory compliance, warehousing, and integrated supply chain solutions. Combined with LP’s global scale, advanced technology platforms, and strong service culture, Manish’s team is well-positioned to deliver comprehensive, end-to-end logistics solutions for customers moving cargo into, out of, and within India.

“Evo Supply Chain was founded just three years ago with a shared vision and strong entrepreneurial spirit,” said Malik. “In a relatively short period, we have built a trusted organization with like-minded professionals and a strong customer base. Becoming part of the Logistics Plus global network allows us to significantly expand our capabilities and global reach, while continuing to deliver the localized expertise, responsiveness, and service mindset our customers value. We are proud of this journey and excited to move forward with Logistics Plus, helping customers navigate increasingly complex supply chains with confidence.”

With the addition of Manish’s team, Logistics Plus continues to expand its global footprint, providing customers with flexible, scalable logistics solutions supported by experienced local teams and a worldwide network of offices.

About Evo Supply Chain Pvt. Ltd.

Evo Supply Chain, a subsidiary of Logistics Plus, Inc., is a global supply chain solutions provider specializing in international freight forwarding, customs and trade compliance, project logistics, warehousing and distribution, and 4PL services. Its supply chain professionals help businesses design and implement efficient, cost-effective solutions to address complex logistics and supply chain challenges. Learn more at in.logisticsplus.com.

About Logistics Plus, Inc.

Logistics Plus, Inc. is a 21st Century Logistics Company™. With annual global sales approaching $1 billion, Logistics Plus is a leading global provider of transportation, warehousing, fulfillment, logistics, project management, business intelligence, technology, and unique supply chain solutions. The company is recognized as one of the fastest-growing privately owned logistics companies, with a presence in over 50 countries worldwide. With its trademark Passion for Excellence™, Logistics Plus is consistently recognized as a great place to work and a top global logistics provider. Learn more at logisticsplus.com.

by Ryan Markiewicz | Jan 30, 2026 | News

Eddie Campos, U.S.-Mexico Cross-Border Operations Manager, was featured on today’s (1/30/26) Business Spotlight program, produced in partnership with WPSE Money Radio. Business Spotlight is a monthly 30-minute program that airs regionally and streams globally.

Eddie Campos, U.S.-Mexico Cross-Border Operations Manager, was featured on today’s (1/30/26) Business Spotlight program, produced in partnership with WPSE Money Radio. Business Spotlight is a monthly 30-minute program that airs regionally and streams globally.

In this month’s Logistics Plus segment, Eddie discusses his background, how Logistics Plus keeps freight moving across the border, the importance of shipment visibility, navigating customs and compliance challenges at the border, and more.

You can listen to a replay of the interview on the Logistics Plus podcasts page or by clicking below on our LP Radio channel on Spotify.

by Scott Frederick | Jan 30, 2026 | News

Logistics Plus, once again, has been profiled as a top third-party logistics (3PL) company by Inbound Logistics magazine for its super-sized 2026 Logistics Planner edition. From managing disruptions to charting the course for the coming years, logistics professionals ride a wave of change and reveal supply chain savvy moves in the latest edition of Inbound Logistics. In both print and digital editions, the annual issue features profiles of leaders in transportation, technology, logistics, and more who are ready to help businesses address upcoming challenges and optimize their supply chains.

Logistics Plus, once again, has been profiled as a top third-party logistics (3PL) company by Inbound Logistics magazine for its super-sized 2026 Logistics Planner edition. From managing disruptions to charting the course for the coming years, logistics professionals ride a wave of change and reveal supply chain savvy moves in the latest edition of Inbound Logistics. In both print and digital editions, the annual issue features profiles of leaders in transportation, technology, logistics, and more who are ready to help businesses address upcoming challenges and optimize their supply chains.

The Logistics Plus profile appears on page 245 of the publication. Logistics Plus also has a full-page advertisement on page 69. Recent LP news is also cited on page 28 and page 194.

You can view PDF versions of the Logistics Plus advertisement and profile by clicking the images below.

by Scott Frederick | Jan 23, 2026 | News

Why Global Supply Chains Need Control Towers Now More Than Ever

Today’s global supply chains are more complex—and more interconnected—than ever before. Manufacturers, retailers, infrastructure developers, and industrial firms must manage thousands of suppliers, carriers, inventory locations, and job sites across multiple countries, regulatory regimes, and transportation modes. Without a centralized operating model, organizations face limited visibility, fragmented data, rising costs, and delayed decision‑making.

Today’s global supply chains are more complex—and more interconnected—than ever before. Manufacturers, retailers, infrastructure developers, and industrial firms must manage thousands of suppliers, carriers, inventory locations, and job sites across multiple countries, regulatory regimes, and transportation modes. Without a centralized operating model, organizations face limited visibility, fragmented data, rising costs, and delayed decision‑making.

This is where Global Supply Chain Control Towers play a critical role.

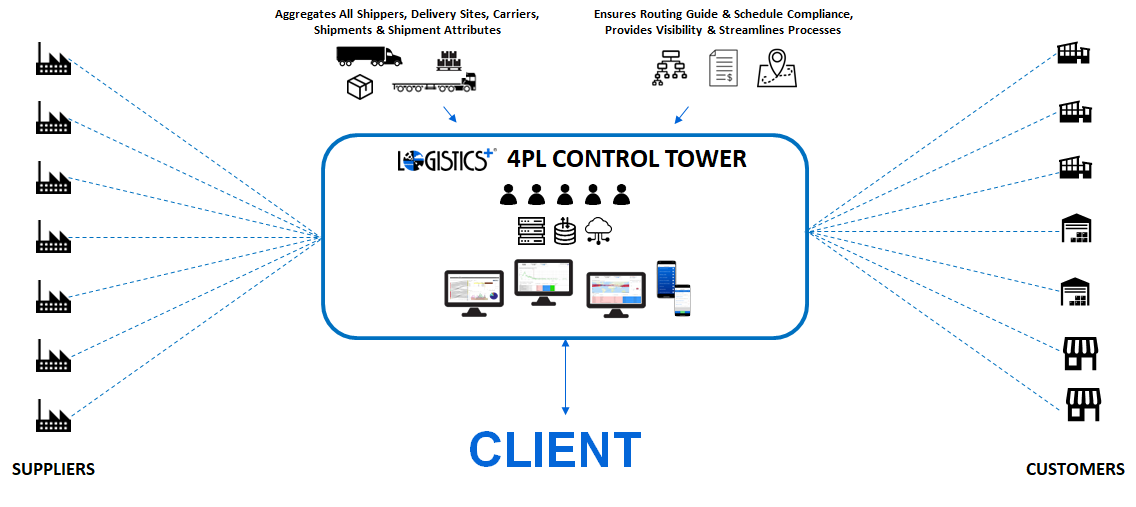

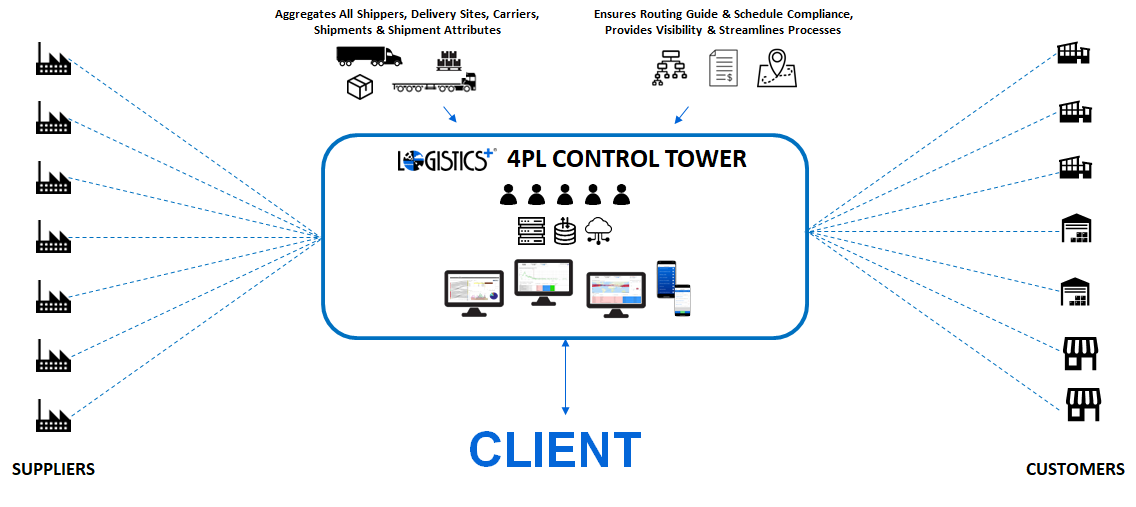

A modern control tower is not just a dashboard – it is a centralized command center that integrates people, process, and technology to deliver real‑time visibility, exception management, performance analytics, and operational control across the entire supply chain. Logistics Plus has been designing, operating, and scaling control tower solutions for some of the world’s most complex and mission‑critical supply chains for decades.

What Is a Global Supply Chain Control Tower?

A Global Supply Chain Control Tower is a centralized 4PL operating model that provides a single source of truth across all supply chain participants—suppliers, carriers, freight forwarders, warehouses, customs authorities, job sites, and internal business stakeholders.

Through a combination of dedicated operational teams and purpose‑built technology, a control tower enables:

- End‑to‑end shipment visibility from purchase order through final delivery

- Centralized routing, scheduling, and execution control

- Proactive exception monitoring and escalation

- KPI tracking, reporting, and business intelligence

- Cross‑stakeholder collaboration across regions, modes, and partners

Logistics Plus delivers this capability through its 4PL Control Tower Solutions, supporting inbound, outbound, domestic, international, and project‑based supply chains worldwide.

How Logistics Plus Control Towers Are Different

Not all control towers are created equally. Logistics Plus combines technology leadership with deep operational execution—ensuring that visibility leads to action, not just reporting.

- A True 4PL Operating Model

Logistics Plus acts as a neutral orchestrator, managing all transportation modes, logistics partners, and suppliers on behalf of the client. The Control Tower team functions as an extension of the customer’s organization—owning planning, coordination, and performance across the full network.

- Dedicated Global Control Tower Teams

Each engagement is supported by dedicated program managers, logistics engineers, analysts, and execution teams operating at the project, regional, and global levels. This structure ensures accountability, scalability, and continuity—whether managing daily flows or peak‑volume events.

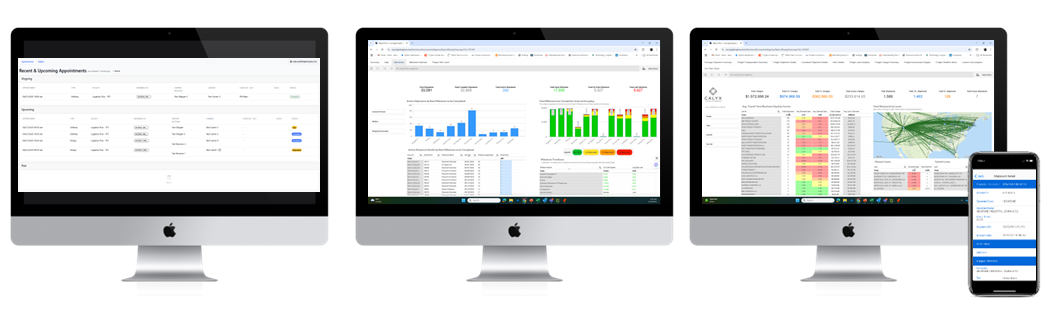

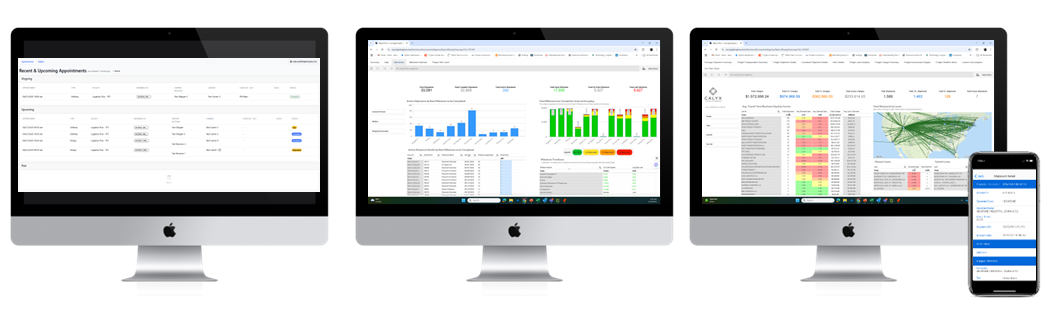

- One Integrated Technology Platform

Logistics Plus leverages its proprietary MyLogisticsPlus™ Control Tower platform to deliver secure, 24×7 access to unified shipment views, dashboards, alerts, and analytics. The platform supports API and EDI integrations, real‑time and milestone‑based tracking, and customizable workflows aligned to each customer’s operating model.

End‑to‑End Visibility Across the Entire Supply Chain

Visibility is only valuable if it is comprehensive, timely, and actionable. Logistics Plus Control Towers provide end‑to‑end visibility across all supply chain stages, including:

- Supplier production and shipment readiness

- Domestic and international transportation (parcel, LTL, TL, air, ocean, rail, intermodal)

- Customs clearance and trade compliance milestones

- Warehouse receiving, inventory, and outbound fulfillment

- Jobsite deliveries, gate scheduling, and on‑site coordination

Advanced GPS and IoT tracking capabilities enable real‑time monitoring of shipment location and condition—including temperature, shock, tampering, and route deviation—allowing proactive risk mitigation before disruptions escalate.

Data‑Driven Control Through Business Intelligence

At the core of every Logistics Plus Control Tower is a robust business intelligence framework. Performance metrics are mutually defined during onboarding and tracked continuously to drive accountability and improvement.

Typical KPIs include:

- On‑time pickup and delivery performance

- Average and variance of transit times

- Carrier and supplier compliance

- Damage and claims ratios

- Dwell times at warehouses and job sites

- Critical path performance for complex projects

Custom dashboards and reports transform raw data into actionable insights—supporting better forecasting, cost control, and strategic decision‑making.

Proven Control Tower Success Across Complex Industries

Logistics Plus Control Towers support large‑scale supply chains across many industries such as manufacturing, automotive, energy, infrastructure, technology, aerospace, healthcare, and retail. The model has been successfully deployed for:

- Global inbound networks with Tier 1 and Tier 2 suppliers

- Major construction and infrastructure projects

- Large‑scale solar and renewable energy developments

- Global FF&E deployments

- High‑volume international distribution programs

In multiple global inbound programs, Logistics Plus has helped clients dramatically improve transit reliability, reduce cycle times, and restore trust across multi‑party networks—by creating transparency, enforcing routing discipline, and driving continuous improvement through data.

Turning Visibility into Competitive Advantage

A well‑executed control tower does more than monitor shipments—it enables organizations to operate with confidence, speed, and precision. By consolidating visibility, execution, and analytics into a single operating framework, Logistics Plus empowers clients to scale faster, control costs, reduce risk, and deliver on customer commitments—no matter how complex the supply chain.

A well‑executed control tower does more than monitor shipments—it enables organizations to operate with confidence, speed, and precision. By consolidating visibility, execution, and analytics into a single operating framework, Logistics Plus empowers clients to scale faster, control costs, reduce risk, and deliver on customer commitments—no matter how complex the supply chain.

About Logistics Plus

Logistics Plus is a global 3.5PL™, 4PL, and supply chain solutions provider with a proven track record of managing complex, multinational logistics programs. With over 1,400 employees in 55+ countries, proprietary technology platforms, and deep operational expertise, Logistics Plus delivers a single pane of glass for global supply chain execution.

by Scott Frederick | Jan 6, 2026 | News

Why “more space” isn’t the goal—network flexibility is.

For Fortune 1000 manufacturers and distributors, warehousing is no longer just a place to store inventory. It’s a performance engine that influences service levels, cash flow, resiliency, and total landed cost. Yet many enterprises are facing the same constraints: labor pressures, rising customer expectations, shifting inventory strategies, and the need to respond quickly when demand or supply conditions change.

That’s why more organizations are turning to outsourced warehousing solutions—not simply to find capacity, but to gain flexible, scalable execution without taking on the fixed cost and complexity of expanding their internal footprint.

1) The market is shifting from “warehouses” to warehouse networks

Enterprise shippers are increasingly optimizing networks, not single buildings. The goal is to place inventory closer to demand, reduce transportation spend, shorten lead times, and build resilience into distribution—particularly during seasonal surges, promotions, port disruptions, and supplier variability.

In practice, that means many Fortune 1000 organizations are adding:

- Regional overflow capacity for peak periods

- Multi-node fulfillment to improve delivery performance

- Staging and transload options to reduce congestion and dwell time

- Flexible contract models that allow for volume swings

This is one reason 3PLs continue to grow in importance as companies outsource more operational complexity, including fulfillment and returns

Where Logistics Plus fits: Logistics Plus describes a North American warehousing network of over 11 million square feet (plus additional warehousing worldwide), designed to be “just the right size, in just the right place, for just the right length of time.”

2) Warehouse labor constraints are accelerating investment in process and technology

Even companies with strong operational discipline are finding that labor availability and cost can change the economics of in-house warehousing. That’s driving renewed emphasis on:

- Standardized processes

- Measurable KPIs and continuous improvement

- Modern labor management approaches

- Technology that makes operations less dependent on scarce labor

Industry outlook coverage continues to highlight labor tightness and efficiency pressure as drivers behind warehouse modernization and automation adoption.

Where Logistics Plus fits: For enterprise customers, the differentiator isn’t “can you warehouse product?”—it’s whether the 3PL can engineer consistent execution across multiple facilities while remaining responsive when requirements change.

3) WMS modernization is becoming a boardroom issue

Many enterprise shippers are discovering that their current WMS environment can’t keep up with new demands—especially in integration, visibility, and automation support. Industry reporting on “next-gen WMS” emphasizes scalability, adaptability, and readiness for AI/automation integrations as critical requirements.

What to ask a 3PL (enterprise-ready tech questions):

- Do your technology solutions integrate with our ERP, OMS, TMS, and carrier stack?

- Do you support EDI/API connections and customer-specific reporting?

- How do you handle inventory accuracy, cycle counts, and traceability?

- What visibility do we get (real-time dashboards, exception alerts, KPIs)?

Where Logistics Plus fits: In warehousing evaluations, LP’s value proposition is positioned as operations-first—solving warehousing challenges in “the real world,” supported by systems and reporting that match enterprise governance needs.

4) “Speed to deploy” is now a differentiator

Fortune 1000 logistics teams are increasingly measured on how quickly they can respond to disruption—without sacrificing compliance or performance. Outsourced warehousing solutions can support:

- Fast overflow capacity during peaks

- Contingency plans for supplier delays

- New product launches and promotions

- Market expansions and new customer onboarding

Where Logistics Plus fits: Logistics Plus can implement warehousing solutions quickly (engineering, labor, process, systems integration), not just offer a rate.

5) The best 3PL partners combine scale and agility

Enterprise shippers often feel stuck choosing between:

- Very large providers that can be slow, rigid, or standardized, and

- Smaller providers that are nimble but limited in network reach or capacity

A strong outsourced warehousing partner bridges that gap: enterprise-grade capability with a hands-on operating model.

Where Logistics Plus fits: The Logistics Plus North American footprint (11M+ sq ft) aligns with scaling expectations, while the company’s positioning emphasizes tailoring solutions to business needs and time horizons rather than forcing “one-size-fits-all” programs.

How to Choose an Outsourced Warehousing Partner

(Fortune 1000 Checklist)

- Network fit

- Do they have the facilities you need—now and in the future?

- Can they support multi-region distribution and growth?

- Operational capability

- Receiving, putaway, storage, pick/pack, outbound

- Cross-dock/transload

- Value-added services (labeling, kitting, light assembly)

- Returns processing (if needed)

- Governance and performance

- SLAs, KPIs, business reviews

- Inventory accuracy and cycle count programs

- Quality and compliance standards

- Technology integration

- WMS visibility and reporting

- ERP/OMS/TMS integration options

- Security posture and data reliability expectations (especially as AI and automation adoption grow)

- Commercial flexibility

- Scalability for peaks and promotions

- Contract structures that match volume reality

- Transparent cost drivers

Why Logistics Plus for Enterprise Warehousing?

Logistics Plus provides warehousing and distribution services across North America, with over 11 million square feet of commercial warehouse space, plus additional global facilities, supporting customers who need flexible solutions and real-world execution.

Logistics Plus provides warehousing and distribution services across North America, with over 11 million square feet of commercial warehouse space, plus additional global facilities, supporting customers who need flexible solutions and real-world execution.

For Fortune 1000 manufacturers and distributors, the ideal outcome is not just outsourced storage—it’s a warehousing program that improves service, lowers total cost, and scales with business change.

If your organization is evaluating outsourced warehousing solutions—for overflow, regional distribution, fulfillment, or network resilience—Logistics Plus can help assess your requirements and recommend a right-sized program for the right locations and timelines.

Talk to our warehousing team to review your network needs and identify capacity options.

Page 2 of 239«12345...102030...»Last »

ERIE, PA (February 4, 2026) – Logistics Plus, Inc. (LP), a global leader in transportation, logistics, and unique supply chain solutions, is proud to be Certified™ by Great Place to Work® for the ninth year in a row. The prestigious award is based almost entirely on what current employees say about their experience working at Logistics Plus. This year, 91% of employees said it’s a great place to work – 34 points higher than the average U.S. company, and 3 points higher than the composite average of the top 100 best companies in America.

ERIE, PA (February 4, 2026) – Logistics Plus, Inc. (LP), a global leader in transportation, logistics, and unique supply chain solutions, is proud to be Certified™ by Great Place to Work® for the ninth year in a row. The prestigious award is based almost entirely on what current employees say about their experience working at Logistics Plus. This year, 91% of employees said it’s a great place to work – 34 points higher than the average U.S. company, and 3 points higher than the composite average of the top 100 best companies in America.

Today’s global supply chains are more complex—and more interconnected—than ever before. Manufacturers, retailers, infrastructure developers, and industrial firms must manage thousands of suppliers, carriers, inventory locations, and job sites across multiple countries, regulatory regimes, and transportation modes. Without a centralized operating model, organizations face limited visibility, fragmented data, rising costs, and delayed decision‑making.

Today’s global supply chains are more complex—and more interconnected—than ever before. Manufacturers, retailers, infrastructure developers, and industrial firms must manage thousands of suppliers, carriers, inventory locations, and job sites across multiple countries, regulatory regimes, and transportation modes. Without a centralized operating model, organizations face limited visibility, fragmented data, rising costs, and delayed decision‑making.

A well‑executed control tower does more than monitor shipments—it enables organizations to operate with confidence, speed, and precision. By consolidating visibility, execution, and analytics into a single operating framework, Logistics Plus empowers clients to scale faster, control costs, reduce risk, and deliver on customer commitments—no matter how complex the supply chain.

A well‑executed control tower does more than monitor shipments—it enables organizations to operate with confidence, speed, and precision. By consolidating visibility, execution, and analytics into a single operating framework, Logistics Plus empowers clients to scale faster, control costs, reduce risk, and deliver on customer commitments—no matter how complex the supply chain.

Logistics Plus provides warehousing and distribution services across North America, with over 11 million square feet of commercial warehouse space, plus

Logistics Plus provides warehousing and distribution services across North America, with over 11 million square feet of commercial warehouse space, plus