by logisticsplus | Aug 5, 2019 | News

Please see the latest supplement to the National Motor Freight Classification (NMFC®) by the Commodity Classifications Standards Board (CCSB). These changes have an effective date of 8/24/2019. A few of the notable changes are listed below.

- Item 171 – Artificial construction of a density to obtain a lower class (the bumping clause) has been cancelled and no longer applies on any NMFC Items.

- All items listed under the Flowers, Herbs or Leaves (NMFC 71500); and Roots or Spices (NMFC 170700) groups are being cancelled and moved to the newly established NMFC 98720 which will carry a 3 sub classification based on density and may be an increase or decrease in class. ***Please see the attached supplement for specific NMFC Items affected.

- Binders or Covers – NMFC 23490 & 23500 are being cancelled and moved under NMFC 179180 which carries an 11 sub classification based on density and may be an increase or decrease in class.

- Cookers, electric, low temperature – NMFC 25930 is being cancelled and moved under NMFC 25840 which is being changed to a flat class 110 and will have an increase in class.

- Cookers, steam pressure (Pressure Cookers) – NMFC 52880 is being cancelled and moved under NMFC 25840 which will be a flat class 110 and newly established NMFC 52960 which will be a flat class 100.

- Heaters, water, tankless – NMFC 26525 is being changed to a 2 sub classification based on density and will be an increase in class.

- Mobility scooter, electric – newly established NMFC 56834 will carry a 2 sub classification based on density.

- Wheelchairs, motor-propelled – NMFC 57070 is being changed to a 2 sub classification based on density and may be an increase or decrease in class.

- Shampoo or Conditioner; and Shaving Cream or Shaving Soap – NMFC 59320 and 59360 are being canceled and moved under NMFC 59420 which is being changed to a 3 sub classification based on density and will be an increase in class.

- Cords, power supply (for permanent attachment to electric appliance, machine or tools) – NMFC 61490 is being changed to a flat class 70 and will be an increase in class.

- Electronic Cigarettes, Vape Device or other Nicotine Delivery System or Subassemblies or Essential Parts – newly established NMFC 61805 will carry an 11 sub classification based on density.

- Telephone Parts and Videophones – NMFC 63285 & 63310 are being canceled and moved under NMFC 63300 which carries an 11 sub classification based on density and may be an increase or decrease in class.

- Carpet or Rug Lining, Cushions or Floor Underlayment – NMFC 70540, 70560, 70580, 70600, 70650 & 70660 are being cancelled and moved under newly established NMFC 70610 which will carry an 8 sub classification based on greatest dimension and density and may be an increase or decrease in class.

- Sneeze Guards or Food Shields – NMFC 82285 is being changed to a 2 sub classification based on the greatest dimension and will be an increase in class.

- Gas Masks – NMFC 85380 is being cancelled and moved under NMFC 134140 which is being changed to class 200 and will be an increase in class.

- Air Coolers, water evaporative type – NMFC 114130 is being changed to an 8 sub classification based on packaging and density and may be an increase in class.

- Drags, Groomers or Rakes (equestrian arena or track – tractor or vehicle attaching) – newly established NMFC 119750 will carry a 2 sub classification based on density.

- Pressure Reducing Valve and Water Relief Valve combined – NMFC 127200 is being cancelled and moved under NMFC 127220 which is being changed to a 3 sub classification based on density and may be an increase or decrease in class.

- Siding, plastic – NMFC 170580 is being changed to an 8 sub classification based on the greatest dimension and density and will be an increase in class.

- Augers or Diggers (post hole, hand held or hand supported) – NMFC 183635 is being changed to an 8 sub classification based on packaging and density and may be an increase in class.

- Windshield Wiper Arms, Blades or Motor – NMFC 197720 is being changed to a flat class 110 and will be an increase in class.

- Cancelled NMFC Items due to being Obsolete:

Asbestos Articles – NMFC 14620

Shoe shining cabinet (household) – NMFC 80380

Oleo Stock – NMFC 145550

Click the thumbnail image below to download a PDF copy of the full list of classification changes.

by logisticsplus | Mar 6, 2019 | News

Logistics Plus recently had the opportunity to participate in an article for DC Velocity magazine. The article, written by Toby Gooley, contributing editor for the publication, offers manufacturers and retailers the following four (4) tips on managing the logistics for a new product launch or rollout (a new, developing area of expertise for Logistics Plus).

Logistics Plus recently had the opportunity to participate in an article for DC Velocity magazine. The article, written by Toby Gooley, contributing editor for the publication, offers manufacturers and retailers the following four (4) tips on managing the logistics for a new product launch or rollout (a new, developing area of expertise for Logistics Plus).

- Provide plenty of advance notice.

- Clearly communicate requirements and expectations.

- Work with your providers to anticipate the new product’s impact on operations and costs.

- Choose a partner with experience in handling new-product launches.

You can read the entire online version of the article here:

https://www.dcvelocity.com/articles/20190306-four-tips-for-a-successful-new-product-launch/

Matt Bosko, senior logistics specialist and project manager, and Scott Frederick, vice president of marketing, were both cited in the article.

by logisticsplus | Dec 4, 2018 | News

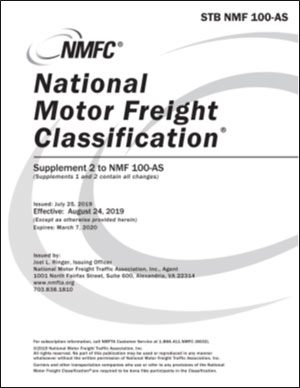

Please see the attached Disposition bulletin from the recent meeting of the Commodity Classification Standards Board. All subject items were approved as docketed or modified as reviewed by the CCSB with the exception to Subjects 5 and 6 which were deferred until the February 2019 meeting. The supplement with the changes to the NMFC will be published on November 29th, 2018 with an effective date of December 29th, 2018. Please review the entire disposition bulletin as many commodities have changed classification.

Please see the attached Disposition bulletin from the recent meeting of the Commodity Classification Standards Board. All subject items were approved as docketed or modified as reviewed by the CCSB with the exception to Subjects 5 and 6 which were deferred until the February 2019 meeting. The supplement with the changes to the NMFC will be published on November 29th, 2018 with an effective date of December 29th, 2018. Please review the entire disposition bulletin as many commodities have changed classification.

Among all of the changes, please make note the following changes for more common commodities that may impact many shipments/customers:

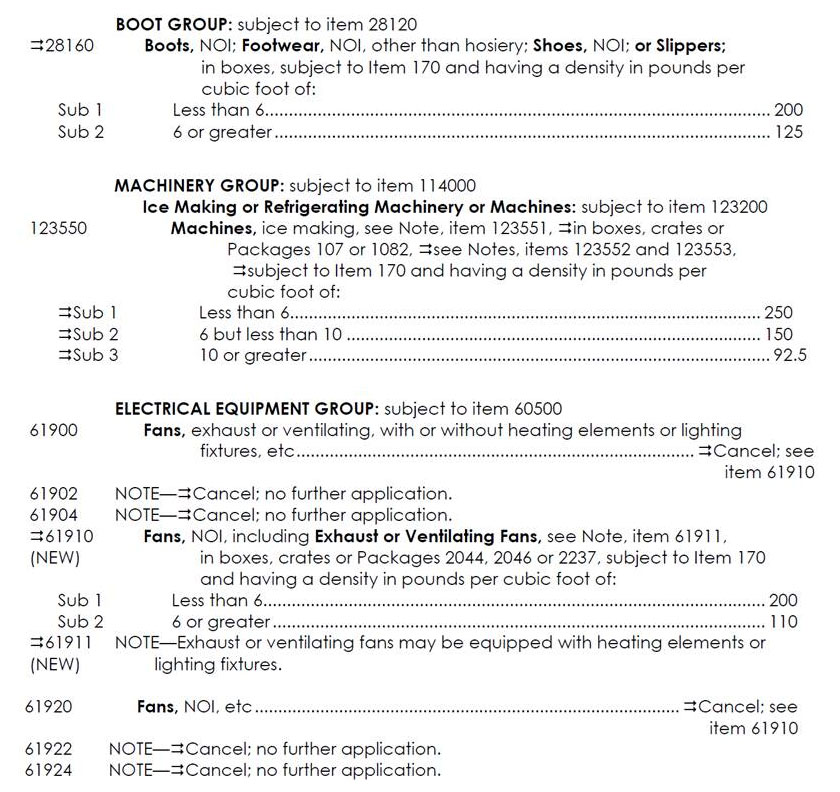

Subject 1: NMFC Item 28160; Boots, NOI, Footwear, NOI, other than hosiery, Shoes, NOI. Will change from a straight class 150 to a two-tier density break. Less than 6 pcf is class 200, 6 pcf or greater is class 125.

Subject 2: NMFC Item 123550; Machines, ice making. Will change from a straight class 92.5 to a three-tier density break. Less than 6 pcf is class 250, 6 but less than 10 pcf is class 150, 10 pcf or greater is class 92.5.

Subject 8: NMFC Items 61900; Fans, exhaust or ventilating and 61920; Fans, NOI are cancelled. New NMFC Item 61910 is created to encompass exhaust/ventilating fans and fans, NOI. This item will have a two-tier density break, less than 6 pcf is class 200, 6 pcf or greater is class 110.

by logisticsplus | Nov 6, 2018 | News

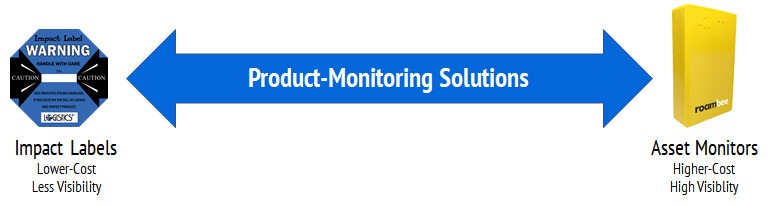

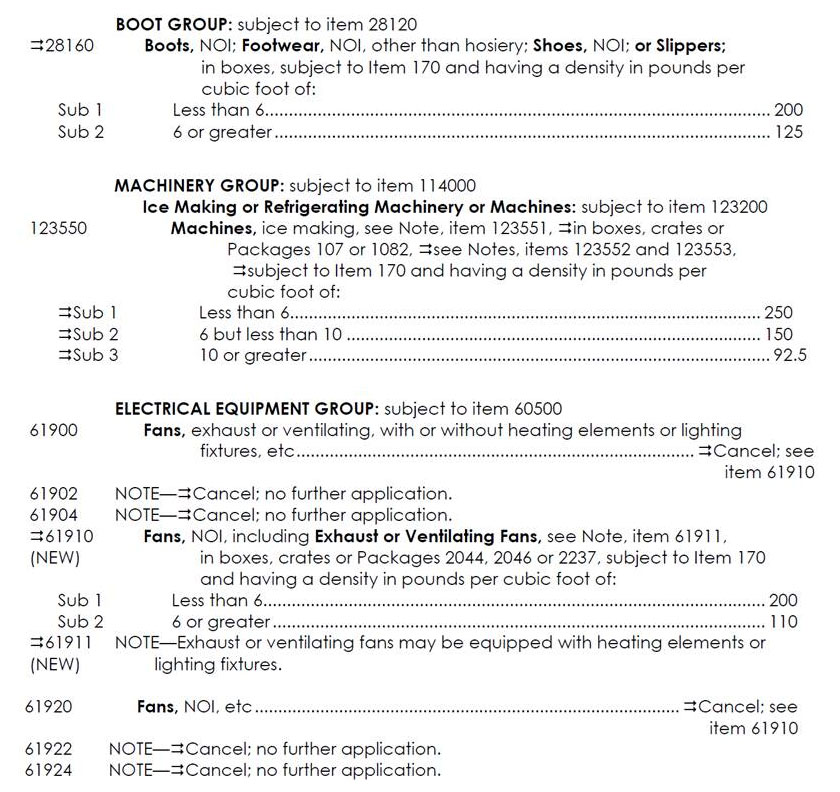

From containers in shipment, to equipment in warehouses, to individual packages … Logistics Plus has you covered with affordable transportation and product-monitoring solutions. Nothing is worse than dealing with the hassle of damaged product deliveries – and concealed damage is among the hardest to spot. If concealed damage is not identified at the time of delivery, proving carrier liability for the damage becomes extremely difficult when filing a freight claim. For that reason, Logistics Plus is offering new “impact labels” to qualified customers who need a low-cost alert system for potential concealed damages.

The new Logistics Plus impact label indicators for packaging deter mishandling and reduce damage related costs by indicating when fragile products have been exposed to a potentially damaging impact during transit or in storage. Impact labels are tamper-proof, mechanically-activated devices that turn bright red when an impact occurs. Standard labels have a sensitivity of 25G, but 37G, 50G, 75G, and 100G labels are also available. If your package sustains an impact of 25G, the indicator in the middle of the sticker will turn red. That means your shipment has been potentially damaged on the inside, and you should open and inspect your shipment before your delivery driver leaves the premises. If damage has occurred, be sure to note it on the signed delivery receipt.

Impact labels are one of many product-monitoring solutions that Logistics Plus is able to provide to shippers. For larger, more complex shipments, or higher-valued assets, RFID and GPS devices (such as Roambees) might be the more appropriate solution. However, if you need basic, low-cost product-monitoring, then impact labels might be the way to go.

Contact Logistics Plus if you’d like to explore any of our asset- and product-monitoring solutions. We’re here to help!

by logisticsplus | Oct 25, 2018 | News

Whether it’s due to cost, delivery time, or increased business opportunities, rethinking your shipping network may be more important than ever. Unfortunately, there is no “one size fits all” approach to creating an optimal shipping network. For one industry, it may be crucial to have strategically placed warehouses across the country. In another industry, it may be more important to deliver products timely across the country. Having an out of date shipping network may be holding back the growth of your business. Follow these tips to help optimize your shipping network today.

Whether it’s due to cost, delivery time, or increased business opportunities, rethinking your shipping network may be more important than ever. Unfortunately, there is no “one size fits all” approach to creating an optimal shipping network. For one industry, it may be crucial to have strategically placed warehouses across the country. In another industry, it may be more important to deliver products timely across the country. Having an out of date shipping network may be holding back the growth of your business. Follow these tips to help optimize your shipping network today.

Create a Strategy

To create a successful shipping network, you must plan, build, and optimize a strategy that best fits your needs. Begin by doing an analysis of your business to determine what is most important to your customers. Would they rather receive packages quicker or get the cheapest shipping rates? Regardless, every shipping network strategy should aim to accomplish two goals:

1.) Decrease the time customers wait for their orders.

2.) Lower your cost per order.

Choose Warehousing Locations

When optimizing a shipping network, location is crucial. Certain areas across the U.S. such as Los Angeles, New York City, and Chicago have become hotbeds for distribution because of their proximity to large parts of the population. Having multiple distribution centers and available warehousing across the country can be a huge benefit for businesses and can help decrease transit times and costs. Have a clear idea of where your customers are located and base your warehousing and distribution strategy on those locations. Having optimal warehouse locations is an important key to a successful shipping network.

Implement Technology Solutions

During the planning stages, business intelligence tools can help model an optimal distribution strategy. After a network has been implemented, a transportation management system (TMS) can be a valuable and time-saving asset for any shipping network. A TMS can give you the best quotes, transit times, and service options to help deliveries and pickups become more efficient and accurate. Along with a TMS, an effective warehouse management system (WMS) allows real-time reporting for order confirmation, tracking activity, received shipments, and more. As technology continues to expand, more efficient and effective solutions for distribution networks are presented. Continuously updating technology is an easy way to keep up with the ever-changing shipping industry.

Look Towards the Future

As the transportation industry constantly changes, it’s important to stay up to date on current and future industry trends. With a severe driver shortage and the capacity crunch, transportation costs will rise significantly. As transportation costs rise, distribution networks will have to gradually expand closer to key market locations to reduce mileage and costs. There is currently a shortage of about 60,000 drivers this year, and it’s estimated that by 2026, the shortage may triple. Another factor of rising transportation costs is fuel cost volatility. Monitoring current and future freight trends is a great way to optimize your shipping network and stay ahead of competition.

Creating an optimized shipping network doesn’t just mean adding more warehouses, it can also mean removing some. It’s important to remember that all businesses have different needs and there is not just one correct way to optimize a shipping network. By creating a proper distribution strategy and implementing it, you can become more efficient while saving time and money.

Page 7 of 12« First«...56789...»Last »

Whether it’s due to cost, delivery time, or increased business opportunities, rethinking your shipping network may be more important than ever. Unfortunately, there is no “one size fits all” approach to creating an optimal shipping network. For one industry, it may be crucial to have strategically placed warehouses across the country. In another industry, it may be more important to deliver products timely across the country. Having an out of date shipping network may be holding back the growth of your business. Follow these tips to help optimize your shipping network today.

Whether it’s due to cost, delivery time, or increased business opportunities, rethinking your shipping network may be more important than ever. Unfortunately, there is no “one size fits all” approach to creating an optimal shipping network. For one industry, it may be crucial to have strategically placed warehouses across the country. In another industry, it may be more important to deliver products timely across the country. Having an out of date shipping network may be holding back the growth of your business. Follow these tips to help optimize your shipping network today.