by logisticsplus | Apr 22, 2022 | News

A recent article published by CSCMP’s Supply Chain Quarterly, written by Jonathon Byrnes and John Wass, suggests that implementing a balanced inventory management strategy is essential. The biggest question facing managers today is whether their supply chains should be just-in-time (low inventories) or just-in-case (high inventories).

A recent article published by CSCMP’s Supply Chain Quarterly, written by Jonathon Byrnes and John Wass, suggests that implementing a balanced inventory management strategy is essential. The biggest question facing managers today is whether their supply chains should be just-in-time (low inventories) or just-in-case (high inventories).

You can read the full article here: How To Resolve Your Inventory Dilemma.

The article focuses on three points concerning inventory management dilemmas. They are presented here with a note under each regarding how Logistics Plus can help.

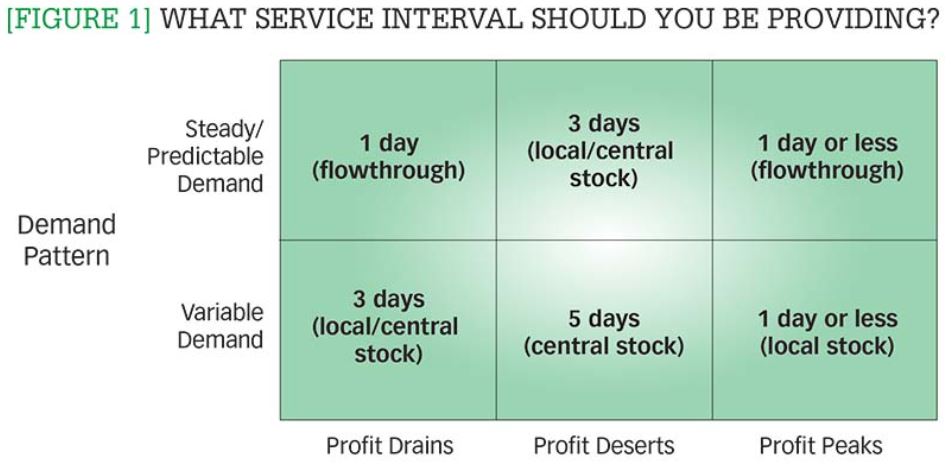

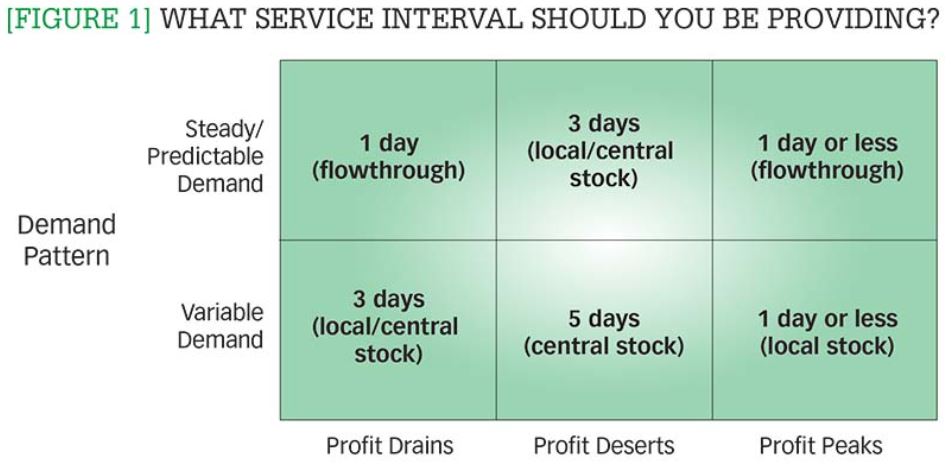

- Make the right promises. A company should offer different service intervals based on the customer profit segment. For example, profit peak customers with steady demand provide your core profitability. These customers should be able to get what they need at any time. Service intervals for profit peak customers should be one-day or less. On the other end of the spectrum are profit drain customers with variable demand. These customers have erratic demand, and it is not necessary to hold high levels of local stock. Instead, these customers should have a service level of about three days, enabling you to bring stock in from a central warehouse. Figure 1 (below) shows the different service intervals based on customer segments.

As a company known for saying YES, not NO, Logistics Plus works with each customer based on their exact needs. We understand that no two customers are the same. Our team offers warehousing and distribution services that are just the right size, in just the right place, for just the right length of time. You don’t pay for space you don’t need. We can diagnose your warehousing challenges, develop inventory management solutions, and then make those solutions work when it matters.

- Manage your account relationships. Customizing your service intervals to match profitability and demand will help keep your inventory low and service levels high. The key to managing account relationships is to be clear about the “rules” of how you will serve your customers. If you keep your promises, retaining your clients becomes more manageable. If profit drain or profit desert customers want the fastest service available, they must pay compensatory prices.

Logistics Plus is committed to providing the best warehousing services possible. Our values reflect our belief in the highest level of service and technology. A focus on delivering the highest level of savings and efficiency is why our clients become long-term customers. We work with customers to ensure their goods arrive at their destination on time and in perfect condition. We provide excellent service and an unwavering commitment to helping them achieve their goals.

- Manage your supply chain. Holding the proper amount of inventory for each customer segment is manageable. By tailoring inventory strategies to each customer profit segment, managers can boost profitability by providing the right set of incentives for each profit segment. For example, Profit peak customers should get consistently fast service with a constant priority on inventory. Profit desert customers should also receive appropriate service promises that they can rely on, giving them an incentive to grow their business and profitability to profit peak status.

As part of your team, we can look up and down your supply chain, identify the weakest links and repair them. You can rely on our team of industry-leading warehouse experts to solve your inventory challenges and significantly improve performance while positively impacting your profitability. By determining the current performance of your supply chain, we can optimize your inventory levels and set up distribution facilities to help you save.

The notes above are just a few thoughts regarding commonly faced inventory dilemmas. Logistics Plus is ready and willing to work collaboratively with our customers to create value and customized solutions that fit their needs. Contact us today to learn more.

by logisticsplus | Mar 2, 2022 | News

Logistics Plus is much more than a leading worldwide provider of transportation, warehousing, fulfillment, global logistics, business intelligence, technology, and supply chain solutions. We manage Global Logistics + So Much More. How do we even begin to describe our various services and solutions with so many capabilities? One way is around these four broad categories:

Logistics Plus is much more than a leading worldwide provider of transportation, warehousing, fulfillment, global logistics, business intelligence, technology, and supply chain solutions. We manage Global Logistics + So Much More. How do we even begin to describe our various services and solutions with so many capabilities? One way is around these four broad categories:

Logistics Plus is a leading manager of LTL (less-than-truckload) freight services, including standard, guaranteed, and volume options, and truckload and expedited freight brokerage services, including dry van and flatbed equipment options.

- Standard Less-Than-Truckload (LTL)

- Volume, Guaranteed & Expedited

- Trade Shows & Events

- Dry Van, Flat Bed & Refrigerated Truckload

- Expedited & Exclusive Use

- Cross-Border U.S. / Canada / Mexico

- Parcel & Small Package

- Rail & Intermodal

- Domestic Air & Ocean

- Freight Audit & Payment

- Freight Claims Management

- eShipPlus™ & MyLogisticsPlus™ Transportation

- Management System (TMS)

- MyFreightTrends™ Dashboards & Analytics

Logistics Plus is a leading international freight forwarder, global trade compliance manager, and award-winning project cargo company.

- Import & Export Services

- Air Freight Forwarding & Air Charters

- Ocean Freight Forwarding (FCL & LCL)

- Hand Carry Services

- Break Bulk & Heavy-Lift Project Cargo

- Over Dimensional, Oversized & OOG

- Customs Clearance & Trade Compliance

- Licensed Customs Brokerage

- Remote Location Filing (RLF)

- Compliance Consulting & Training

- Free Trade Agreement Compliance & Audits

- Importer of Record (IOR) & Exporter of Record (EOR)

- Amazon International Shipping

- eWorldPlus™ & MyLogisticsPlus™ Cargo Management Tools

Logistics Plus is a top dry storage warehousing firm, with nearly 3 million square feet across North America, with additional facilities worldwide. Our final-mile installation capabilities provide turnkey solutions for FF&E, OS&E, and IT infrastructure industries.

- Inbound & Outbound Turnkey Process

- Inventory Management

- Pick, Pack & Ship

- Order Entry & Reporting

- Call Center & Returns Management

- Amazon Prep & Storage

- FBA & FBM Services

- Final Mile Deliveries & Installations

- Warehouse Management Systems (WMS)

Logistics Plus is a leading 3.5PL™ and 4PL company and an experienced provider of dedicated logistics, supply chain management, and technology solutions. Our global supply chain control towers, business intelligence tools, and shipment visibility applications make us a technology company as much as we are a logistics provider.

- 4PL & Supply Chain Consulting

- Dedicated On-Site Resources

- Global Sourcing & Procurement

- Total Claims Management

- LP FAS™ Freight Audit & Payment Solutions

- Shippers’ Interest Cargo Insurance

- Linguistics & Translation Services

- Global Supply Chain Control Towers

- Mobile App for Warehousing & Tracking

- MyLogisticsPlus™ Global Dashboards & Business Intelligence

- Industry-Specific Solutions:

- Aerospace, Aviation & Defense

- Alcohol & Spirits

- Chemicals & Refining

- Energy, Solar & Fuel

- Furniture, Fixtures & Equipment (FFE)

- Financial Services, Data Servers & Technology

- PPE, Pharmaceuticals & Healthcare

- Retail & Distribution

- Startups, Emerging Companies & More!

We are a 21st Century Logistics Company™. With our trademark Passion for Excellence™, we put the + in logistics by doing the big things properly, plus the countless little things that ensure complete satisfaction and success. Are you interested in learning more? Contact us today!

by logisticsplus | Feb 28, 2022 | News

A recent article published in Logistics Management magazine and online at Supply Chain Management Review, written by Sara Banks from Accenture, suggests a strong collaboration between 3PLs and shippers can help to bring innovative solutions that will benefit both in the future. You can read the full article here: Time For Shippers & 3PLs to Innovate Together.

A recent article published in Logistics Management magazine and online at Supply Chain Management Review, written by Sara Banks from Accenture, suggests a strong collaboration between 3PLs and shippers can help to bring innovative solutions that will benefit both in the future. You can read the full article here: Time For Shippers & 3PLs to Innovate Together.

Accenture’s research shows four capabilities shippers want from logistics companies. They are presented here with a note under each regarding Logistics Plus.

End-to-end services. Shippers are looking for a one-stop shop for all logistics services. This means that, beyond basic logistics, they want a trusted logistics provider that delivers new services such as advisory and supply chain consulting services, analytics capabilities, e-commerce channel management capabilities, and even algorithms that match demand and supply.

End-to-end services. Shippers are looking for a one-stop shop for all logistics services. This means that, beyond basic logistics, they want a trusted logistics provider that delivers new services such as advisory and supply chain consulting services, analytics capabilities, e-commerce channel management capabilities, and even algorithms that match demand and supply.

Logistics Plus has evolved by both necessity and design over the past 25 years. As a company known for saying YES, not NO, to unique supply chain challenges, we’ve developed a network of solutions that span the entire supply chain, from procurement to warehousing to final mile delivery. We call this Global Logistics + So Much More. With our 3.5PL and 4PL solutions, we strive to provide the end-to-end services our customers require so that they can remain focused on what they do best: making and selling great products.

- Better experiences. Shippers want a logistics partner that knows their business and will work with them to overcome challenges by bringing in customer-centric solutions. Our research revealed the need for 3PLs to build service consistency, flexibility, and responsiveness to create more satisfying customer experiences.

We are hardly perfect, but there is one trait that shippers can expect when they work with Logistics Plus: a contagious passion for excellence. It’s that passion that has enabled Logistics Plus to earn numerous service and workplace awards and to have positive word-of-mouth referrals that have supported our continuous growth. It may seem like a small thing, but every one of our employees is provided a mobile phone with the expectation that our customers need and deserve flexible, 24/7/365 support. The freight never stops moving.

- Proactive, data-driven insights. Shippers are eager to partner with 3PLs that have data and analytics capabilities to provide visibility and insights to help them make better supply chain decisions. For example, digital twin capabilities that tap into data to simulate supply chain impacts will help 3PLs guide shippers in decisions with more certainty.

We like to point out that today, Logistics Plus is as much a technology company as a logistics company. And that is not by accident. The demands of our customers have driven us to make substantial investments in technology and business intelligence applications. Our global supply chain control towers and business intelligence tools are world-class. We know that information and insights are just as critical in today’s supply chain as are shipments and freight.

- Purpose aligned to their values. Increasingly, shippers are choosing to work with businesses that are more integrated with theirs and share their values. For example, in the logistics space, sustainability is a key issue and becoming a “must-have” requirement for all players.

Shippers looking to align themselves with a 3Pl focused on employee diversity and environmental sustainability will find that Logistics Plus shares those same values. The 50 country flags that fly on top of our global headquarters, each representing the nationality of one of our employees, showcase our celebration of diversity. The fact that we were the first global 3PL to receive Plastic Neutrality Certification for offsetting 19 tonnes of plastic use in 2020 is a testament to our commitment to making the world a better place.

The notes above are just a few thoughts regarding these four capability areas that are important to shippers. Logistics Plus is ready and willing to work collaboratively with shippers to create value and share in the benefits. Contact us to learn more.

by logisticsplus | Feb 16, 2022 | News

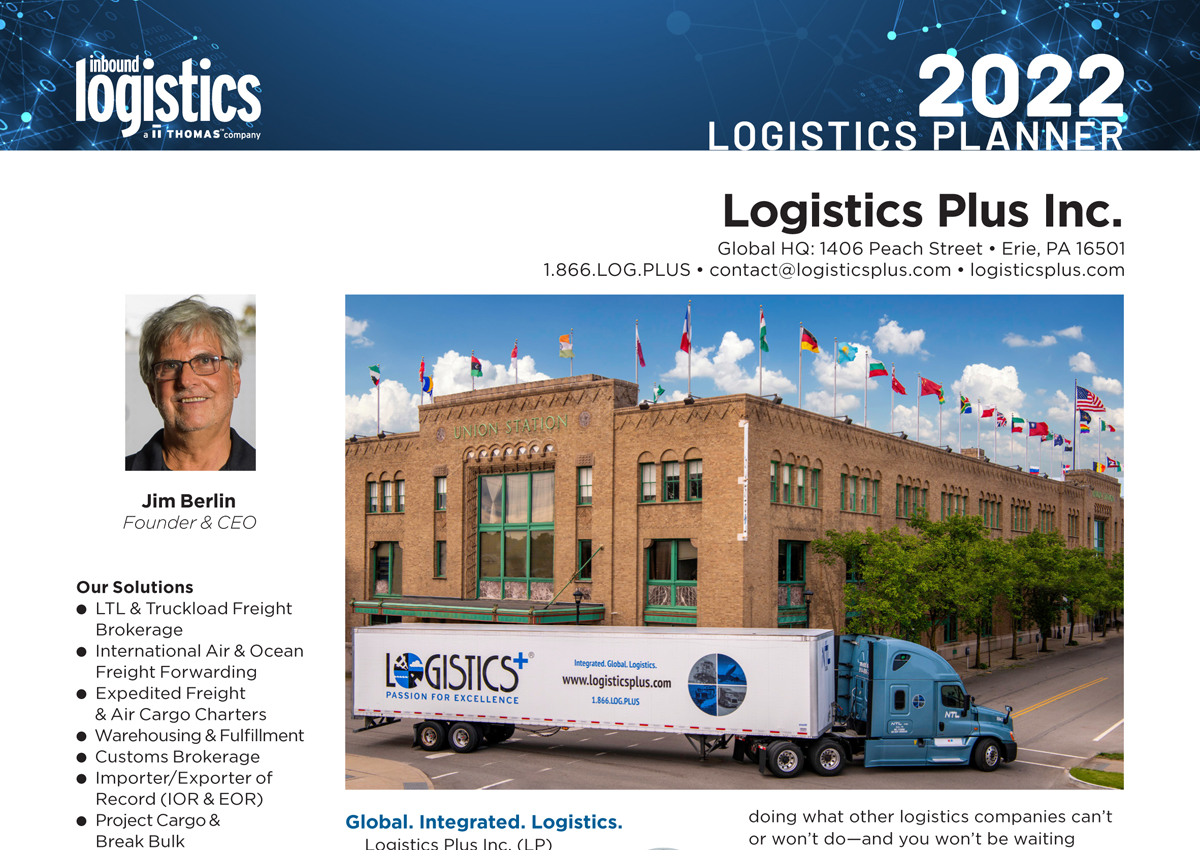

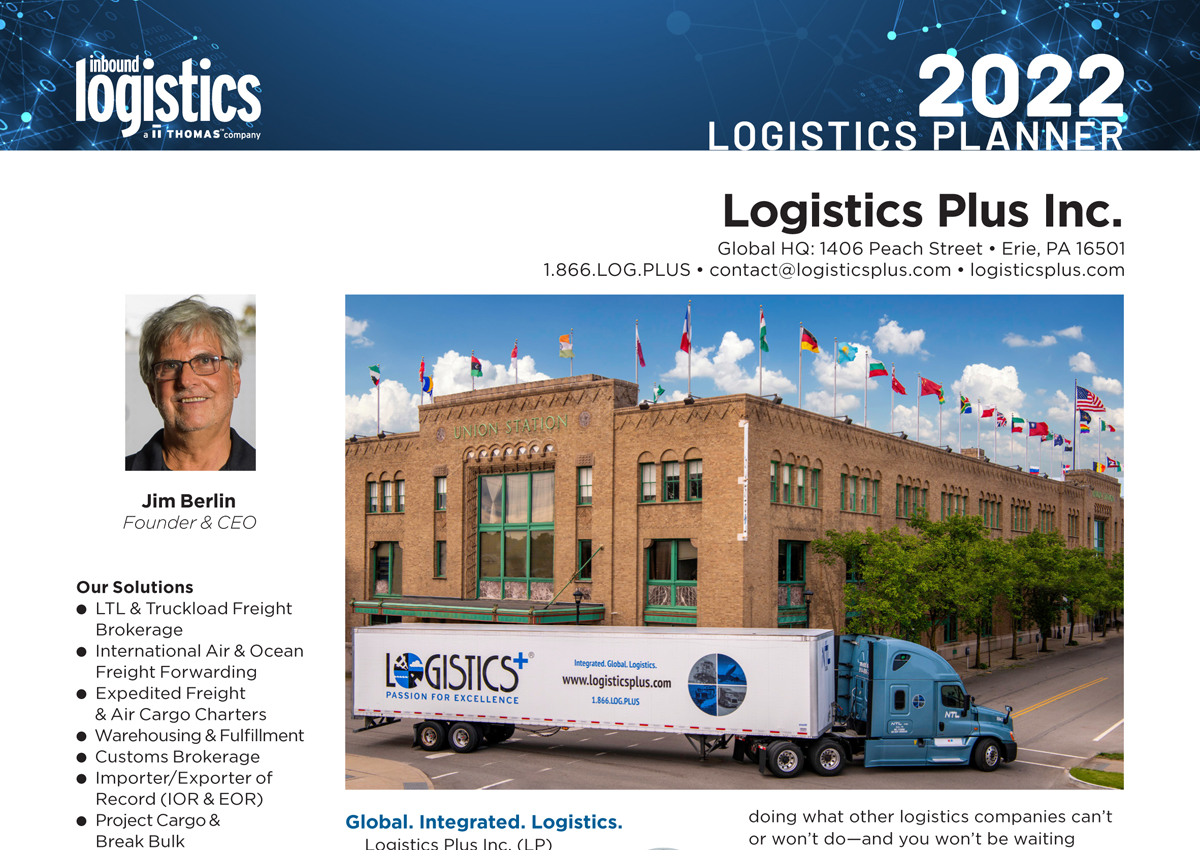

Logistics Plus has, once again, been profiled as a top third-party logistics (3PL) company by Inbound Logistics magazine for its annual Logistics Planner. In its 30th year of publication, the 2022 industry planner helps companies find the right technology solutions and transportation and logistics partners to drive supply chain efficiency. With both print and digital editions, the annual issue is updated with profiles of leaders in transportation, technology, logistics, and more who stand ready to help businesses face upcoming challenges to optimize their supply chains.

Logistics Plus has, once again, been profiled as a top third-party logistics (3PL) company by Inbound Logistics magazine for its annual Logistics Planner. In its 30th year of publication, the 2022 industry planner helps companies find the right technology solutions and transportation and logistics partners to drive supply chain efficiency. With both print and digital editions, the annual issue is updated with profiles of leaders in transportation, technology, logistics, and more who stand ready to help businesses face upcoming challenges to optimize their supply chains.

The Logistics Plus profile appears on page 348 of the publication, and an accompanying advertisement appears on page 137. The profile and advertisement formally present our new theme “Global Logistics + So Much More” as a follow-up to A 21st Century Logistics Company™ introduced last year.

Working as your 3PL, 3.5PL, or 4PL partner, Logistics Plus is the company that handles supply chain challenges from start to finish by doing what other logistics companies can’t or won’t do. We’re small enough to be agile and responsive to your needs, yet large enough to have a network of solutions that span your entire supply chain.

You can view PDF versions of the Logistics Plus profile and advertisement by clicking the two images below.

You can view the entire 2022 Logistics Planner digital edition online here: https://www.inboundlogistics.com/cms/digital/

by logisticsplus | Feb 14, 2022 | News

Each year, 100 million+ viewers worldwide tune in for the Super Bowl. They watch the national anthem, coin toss, opening kickoff, halftime show, funny commercials, and the game (obviously). What the viewers don’t see is the countless amount of hours spent planning and pulling off one of the most significant events of the year. From logistics to transportation to supply chain management, NFL venues undergo extensive preparation for the big day. Let’s take a look at some of the most significant supply chain management considerations for Super Bowl Sunday.

Each year, 100 million+ viewers worldwide tune in for the Super Bowl. They watch the national anthem, coin toss, opening kickoff, halftime show, funny commercials, and the game (obviously). What the viewers don’t see is the countless amount of hours spent planning and pulling off one of the most significant events of the year. From logistics to transportation to supply chain management, NFL venues undergo extensive preparation for the big day. Let’s take a look at some of the most significant supply chain management considerations for Super Bowl Sunday.

Preparing The Venue

The stadium and NFL personnel must coordinate with their employees, vendors, teams, and volunteers to ensure that equipment, uniforms, and the field are all ready in advance of the game. The transportation piece of the supply chain management plan is crucial so that the players’ helmets, cleats, pads, and jerseys all make it to the proper locker room. On top of that, the coaches, medical staff, and other team members all have equipment of their own that must arrive at the venue. Merchandising is another supply chain consideration for the venue. Branded merchandise for each team needs to be designed, manufactured, shipped, and made available within a two-week time frame.

The Halftime Show

The biggest logistical challenge behind the Super Bowl halftime show is setting up the stage the minute the first half of the game ends. The stage is typically wheeled onto the field using roughly fifty carts, each requiring ten people to move. On top of the stage, an additional twenty carts carrying audio equipment get transported to the field. In the days leading up to the Super Bowl, hundreds of trucks arrive at the venue with stage materials, props, electrical equipment, generators, and much more. Every minor detail, including delivery windows, returns and item replacements, and storage locations, is considered.

Supply Chain Sustainability

Over twenty years ago, the NFL introduced an environmental program that focuses on sustainability efforts for the Super Bowl. The league considers many things when selecting the next Super Bowl site, with sustainability efforts being a high priority. For example, Super Bowl LIII was at Mercedez-Benz Stadium in Atlanta, Georgia. Being a newer stadium, it boasted many sustainability features, including its LEED certification. The building uses about half as much water as other stadiums of similar size. Additionally, the NFL’s environmental program works with nearly ninety non-profit organizations to help repurpose, recycle, and reuse materials treated as waste during the game.

Viewers At Home

The city where the Super Bowl is hosted is not the only location with supply chain management challenges. The Super Bowl is the second-largest food-eating day in the United States behind Thanksgiving. It is estimated that 1.3 billion chicken wings are consumed, 11.2 million pounds of potato chips are eaten, and 325 million gallons of beer are drunk in just one day. Around the country, that puts a tremendous amount of stress on local restaurants, grocery stores, and beer distributors to keep up with demand.

Although the game only lasts a few hours, planning and preparing for the Super Bowl takes months. Proper supply chain management is the backbone of what makes the biggest game of the year a constant success. Ensure you give the appropriate planning and preparation needed for your own company’s supply chain. If you need a partner for any of that, let us know – we’re here to help!

Page 6 of 14« First«...45678...»Last »

A recent article published by CSCMP’s Supply Chain Quarterly, written by Jonathon Byrnes and John Wass, suggests that implementing a balanced inventory management strategy is essential. The biggest question facing managers today is whether their supply chains should be just-in-time (low inventories) or just-in-case (high inventories).

A recent article published by CSCMP’s Supply Chain Quarterly, written by Jonathon Byrnes and John Wass, suggests that implementing a balanced inventory management strategy is essential. The biggest question facing managers today is whether their supply chains should be just-in-time (low inventories) or just-in-case (high inventories).

Logistics Plus is much more than a leading worldwide provider of transportation, warehousing, fulfillment, global logistics, business intelligence, technology, and supply chain solutions. We manage

Logistics Plus is much more than a leading worldwide provider of transportation, warehousing, fulfillment, global logistics, business intelligence, technology, and supply chain solutions. We manage

A recent article published in

A recent article published in  End-to-end services. Shippers are looking for a one-stop shop for all logistics services. This means that, beyond basic logistics, they want a trusted logistics provider that delivers new services such as advisory and supply chain consulting services, analytics capabilities, e-commerce channel management capabilities, and even algorithms that match demand and supply.

End-to-end services. Shippers are looking for a one-stop shop for all logistics services. This means that, beyond basic logistics, they want a trusted logistics provider that delivers new services such as advisory and supply chain consulting services, analytics capabilities, e-commerce channel management capabilities, and even algorithms that match demand and supply.

Each year, 100 million+ viewers worldwide tune in for the Super Bowl. They watch the national anthem, coin toss, opening kickoff, halftime show, funny commercials, and the game (obviously). What the viewers don’t see is the countless amount of hours spent planning and pulling off one of the most significant events of the year. From logistics to transportation to

Each year, 100 million+ viewers worldwide tune in for the Super Bowl. They watch the national anthem, coin toss, opening kickoff, halftime show, funny commercials, and the game (obviously). What the viewers don’t see is the countless amount of hours spent planning and pulling off one of the most significant events of the year. From logistics to transportation to